The Industrial Internet of Things (IIoT) and edge computing enable the creation of data platforms for more flexible and energy-saving manufacturing. There is the potential to virtualize today's existing decentralized and mostly always-on control technology and to outsource control functions to an edge cluster.

Not only does this enable new business models, such as "on-demand" or "pay-per-use", but optimized resource utilization can also save energy and hardware. The combination of IIoT standards, such as OPC Unified Architecture (OPC UA) / Time Sensitive Networking (TSN), with semantically coordinated information models, such as the functional submodels of the Industrie 4.0 management shell, also enables automatic configuration and thus rapid conversion of production lines.

There are three scientific challenges here:

- The engineering of an end-to-end deterministic real-time data transmission and processing

- The integration of the above standards

- Ensuring IT security

Crosstep - the Edge Computing Platform in SmartFactoryOWL

To address the above challenges, Fraunhofer IOSB is developing an open edge platform - CrossTEP - especially for the virtualization of Programmable Logic Controllers (PLC) - VirtualPLC. CrossTEP is based on Kubernetes (K8S) for orchestrating Docker containers on the distributed nodes of a cluster. The Docker containers contain applications, in this use case IEC 61131 runtime environments for machine control.

The runtime environments are deterministically connected to machines and their peripherals using OPC UA and TSN. Furthermore, the architecture of CrossTEP is designed to easily apply machine learning techniques and to connect web-based dashboards. These applications can be fed directly from the process image of the virtualized controller and thus generate added value, e.g. in the form of anomaly detection.

Evaluation based on the TableSort bulk material sorting system

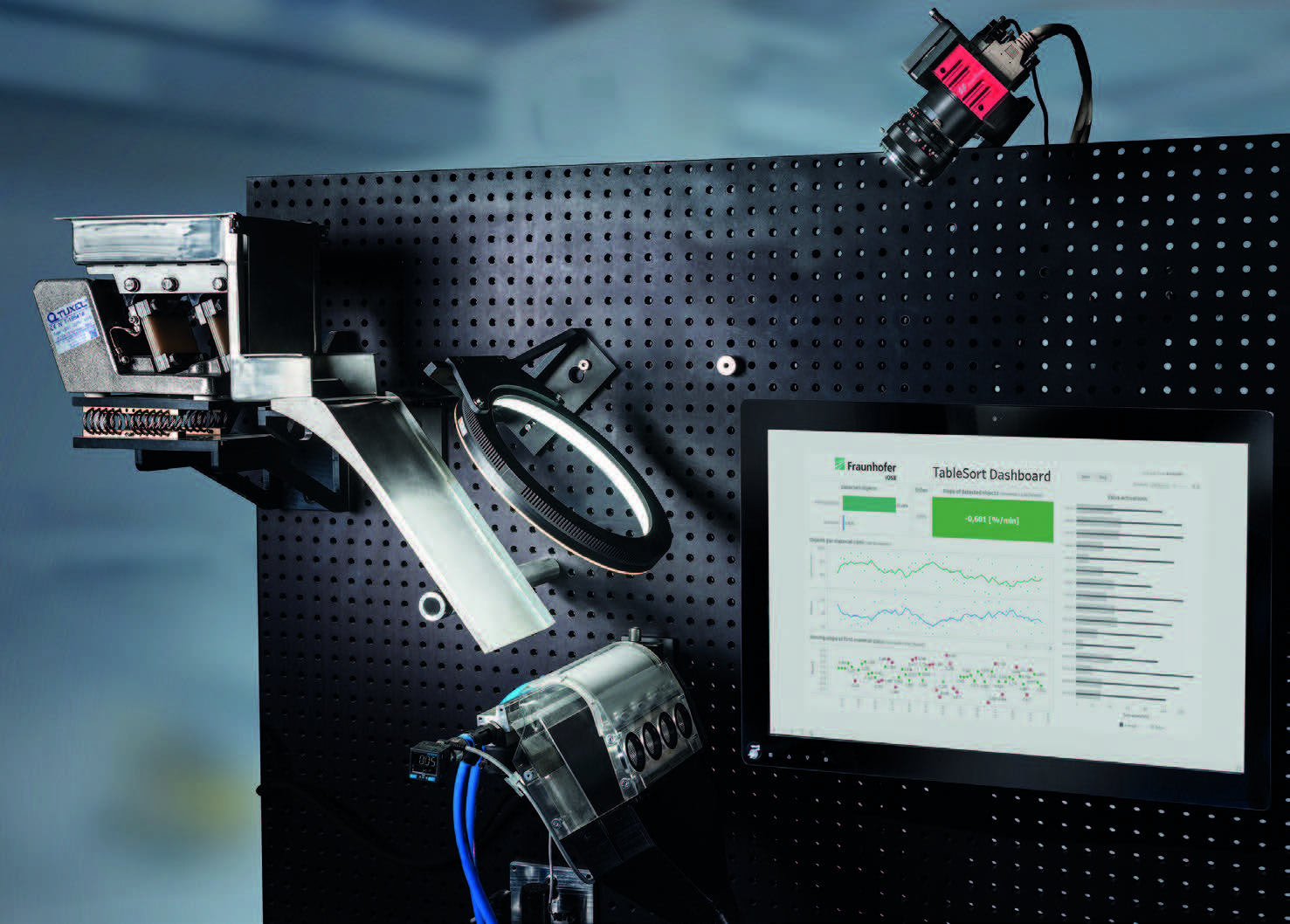

The Fraunhofer IOSB product "TableSort" shown in Figure 2 is a miniature version of a table-sized bulk material sorting system. The sorting mechanism of the "TableSort" works via image capture and processing as well as the real-time critical control of pneumatic nozzles. In SmartFactoryOWL, a "TableSort" is controlled by a CrossTEP application on the edge cluster shown in Figure 1. In addition, an Industrie 4.0-compliant digital twin of the "TableSort" runs on CrossTEP, which was implemented in the form of the management shell based on the OPC UA Companion Specification "I4AAS1". The Digital Twin enables automatic data integration into the web-based dashboard shown in Figure 2 as well as an anomaly detection application also running on the CrossTEP.

Summary

With CrossTEP, Fraunhofer IOSB offers a flexible and extensible edge platform for real-time control and optimization as well as the development and operation of Industrie 4.0-confromer digital twins. CrossTEP combines open edge cloud IT with the latest OT and Industrie 4.0 standards such as the management shell, OPC UA and TSN. In this way, savings potentials can be realized and new production lines can be easily integrated into "on-demand" services.

Industrial Automation branch INA

Industrial Automation branch INA