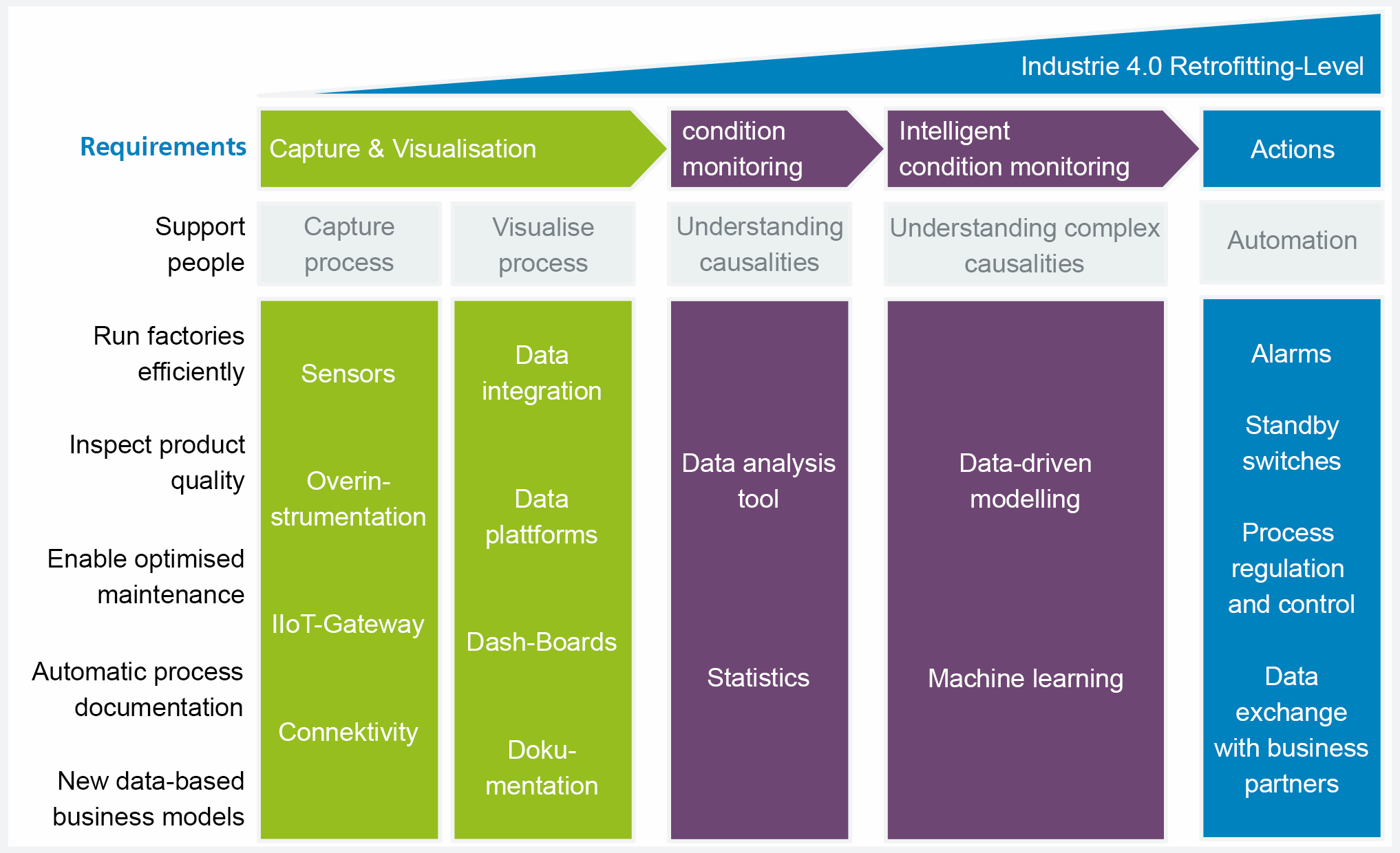

A key function of Industrie 4.0 applications is the acquisition of process data by means of powerful sensor technology. Detailed data collection and evaluation form the basis for increased performance and efficiency.

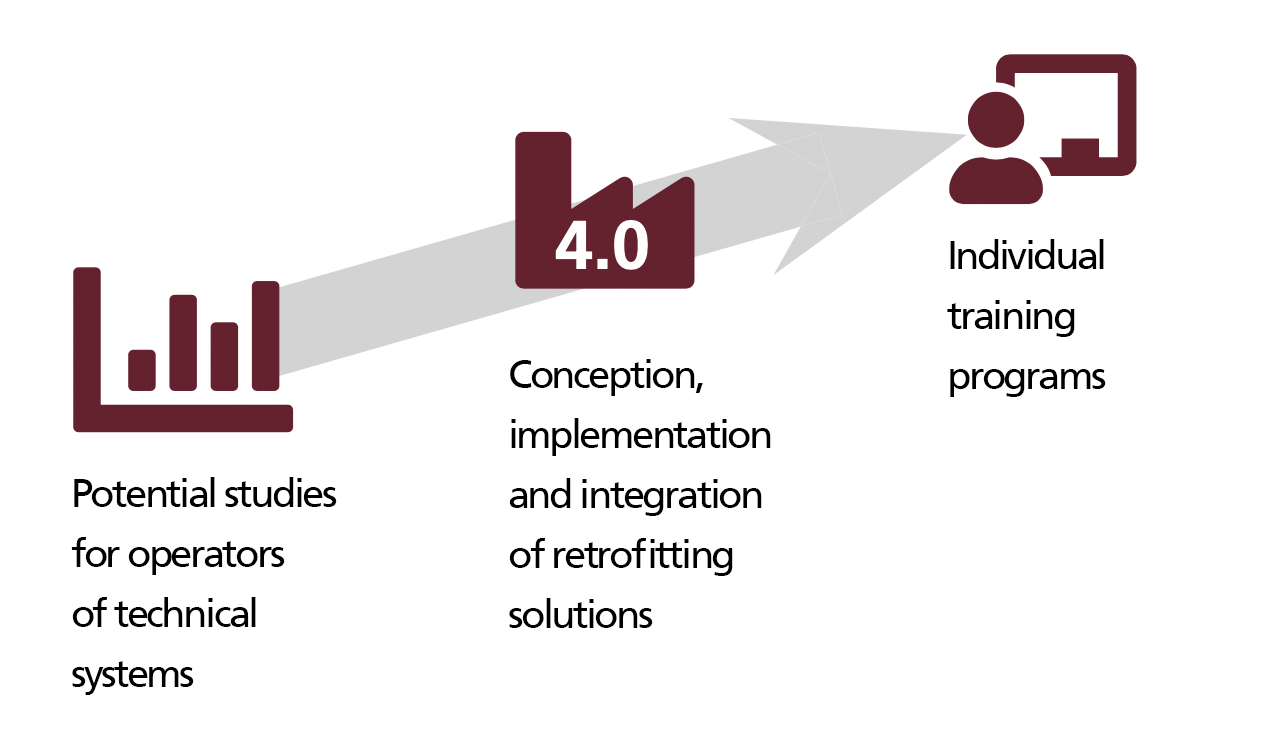

Implementing Industrie 4.0 applications usually requires cost-intensive investments in new infrastructures as well as the replacement of existing machines due to missing Industrie 4.0 interfaces and insufficiently accessible machine data. More cost-efficient are so-called retrofitting solutions, which functionally upgrade existing machines and integrate them into an Industrie 4.0 network. How this can be implemented conceptually and step by step has been elaborated by Fraunhofer IOSB-INA in cooperation with the VDMA in the Industrie 4.0 Retrofit Guide.

Industrial Automation branch INA

Industrial Automation branch INA