Hannover / April 22, 2024 - April 26, 2024

Fraunhofer IOSB-INA at the Hannover Messe 2024

Hall 7, Stand D27 & Hall 14, Stand H06 "5G Arena"

Hall 7, Stand D27 & Hall 14, Stand H06 "5G Arena"

Hall 7, Stand D27: it's OWL joint stand

Hall 7, Stand D27: it's OWL joint stand

As a showcase and connecting element of the trade fair presentation, Fraunhofer IOSB-INA will be presenting a combination of a driverless transport module and an attachment with robot technology. The transport module can use intelligent imaging processes (including LiDAR) to record the terrain and save it as a map, travel to predefined routes and waypoints, process work protocols and recognize obstacles. The attachment with robotic gripper arm (Universal Robots) is equipped with different capabilities and tool attachments. Like the transport module, the robot does not need to be enclosed and can work collaboratively with humans. The robot receives new "capabilities" from the Industrial App Marketplace, and the performance data is made available live via the Stäubli Industrial Connector 4.0 in the Asset Administration Shell (AAS). The combination of all these technologies and the flexibility provided by the modular components ensure a resource-efficient, sustainable production environment tailored to requirements. Additional, automated safety analyses provide an outlook on new safety standards and the simplification of safety checks in changing production setups.

Hall 7, Stand D27: it's OWL joint stand

In future, apps for Industry 4.0 applications will be purchased on online marketplaces. The focus on openness, interoperability and open source gives end users the greatest possible benefit in their day-to-day work. It does not matter whether they are machine operators, machine builders, system integrators or APP developers. The Industrial APP Marketplace establishes a manufacturer-neutral marketplace for I4.0 components for buying and selling industrial hardware, software and services. APPs are generally understood to be modern software applications with a modular structure and a user-friendly web browser interface, but also services and solutions in the context of an Industrial APP Marketplace. A participant in an Industrial APP Marketplace can take on four roles: the role of APP user, hardware developer, APP developer or integrator. The APP user is looking for specific services or solutions, e.g. data acquisition, process visualization, predictive maintenance, etc., which are offered on the Industrial APP Marketplace. The APP developer, hardware developer and integrator place their software, products and services on the Industrial APP Marketplace as a dealer. APP users can add products and services to their shopping cart and receive suggestions for suitable combinations of SW/HW and possible integrators.

Hall 7, Stand D27: it's OWL joint stand

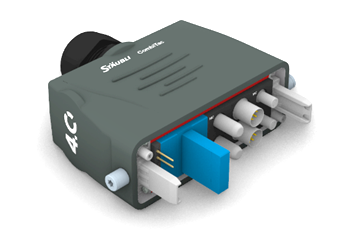

Stäubli EC presents its smart electrical connector concept "Industrial Connector 4.0", which connects Fraunhofer IOSB-INA's AGV robot module to matrix production sites and enables seamless implementation of various data-driven services. The Industrial Connector 4.0 is based on the modular CombiTac connector and built-in sensors that can measure a variety of physical parameters such as temperature, pressure, humidity, vibration and more. Equipped with an Asset Administration Shell, the Industrial Connector 4.0 becomes a mature, interoperable Industry 4.0 component.

By physically connecting components, the connector can make a decisive contribution to increasing sustainability through sensor technology and corresponding data-driven services for process, system and component monitoring: processes become more efficient and the life cycles of systems and components are extended.

Hall 7, Stand D27: it's OWL joint stand

Implementing Industry 4.0 means exploiting the benefits of digitalization in production and developing new, sustainable business models that incorporate the entire value chain sensibly and efficiently. With the FactorySandbox, Industry 4.0 is (co-)designed and implemented in practice. Here, we are working on the specific issues that industry partners face in practical implementation: The use of data across the entire supply chain, the product carbon footprint and the implementation of the circular economy based on the Asset Administration Shell (AAS) and the digital product passport.

Hall 14, Stand H06, 5G Arena